Wanted: apprentices. Must love work

Why programs that blend work-based learning and traditional academics might be the future of higher education.

Traditional academics or vocational training? It’s a question that’s been debated in higher education circles since what seems like the beginning of time.

But for Stephen M. Jordan, Ph.D., president of Metropolitan State University of Denver, the answer is simple: “A great education should give students both.”

Jordan cites the Swiss apprenticeship model as a pertinent example. Even though college is free in Switzerland, nearly 70 percent of young people in the country opt into the Vocational Education and Training system, which puts them to work three days a week. The other two days are spent in the classroom. Companies from a wide variety of industries employ these paid apprentices, including the business, information technology and health care sectors, as well as traditional trades and crafts.

Last winter, Jordan had an opportunity to see the Swiss model in action, when he joined Gov. John Hickenlooper and other Colorado leaders on a trip to learn about the VET program.

“The companies see apprenticeships as an investment in the future,” said Jordan. “They aren’t just teaching the students skills; they’re grooming the next generation of leaders. These programs are similar to those we’ve developed and are developing at MSU Denver, and I think higher education as a whole is moving in this direction. We’re aiming to lead the way.”

Locked in on jobs

Rubi Solis designs parts for satellites. You know, the kind that orbit the earth in space.

And if that isn’t impressive enough in its own right, here’s something more: Solis is doing that work as part of her undergraduate education at MSU Denver.

The electrical engineering technology major is one of six students participating in a co-op program at Lockheed Martin Space Systems Company this year.

“It is amazing to think that a little piece of me will be in space,” said Solis of the project. “The experience has taught me so much already and it has pushed me to go above and beyond what I even expected of myself.”

The co-op program is a collaboration between MSU Denver and Lockheed Martin. Students take a slightly decreased course load, so they can focus on the work experience for two full semesters. They work 20 to 25 hours each week in areas such as 3-D printing, electronics, composite development and even spacecraft testing. More intensive than a traditional internship, the program places students in roles with greater responsibility and pays well.

Solis is part of the second cohort of students to participate in the program, the 2016-17 class. The inaugural group of seven students began their training in September 2015. Of that initial group, six continue to work at Lockheed Martin, five in a full-time capacity. Two students from the second cohort graduated in December and were offered full-time jobs.

For Mark Yoss, production principal at Lockheed Martin, the program is accomplishing its primary goal.

“We are creating a workforce pipeline, getting talented people to come and work for our company,” he said. “And the students are making significant contributions to our mission while they’re still in school. By those measures, the partnership has been a real success.”

At a time when finding talented and diverse employees has been a challenge for aerospace and advanced manufacturing companies across Colorado, the co-op program has helped meet a real need.

As for Solis, she hopes to stay on with Lockheed Martin when she graduates in 2017. But for now, she has plenty on her plate: simple stuff, like designing a circuit board for a valve driver on a military satellite.

Credit where credit is due

Skilled trade workers don’t get nearly enough credit.

They place the pipes in our homes and install the HVAC systems that keep us comfortable at work. Yet because their handiwork often goes unseen, craft workers don’t always get recognized for their contributions.

A new program aims to change that, to give tradespeople credit for the work they do – college credit.

The first-of-its-kind program was developed by MSU Denver and RK, a regional leader in mechanical contracting and custom manufacturing, and was intended to help RK employees move into leadership roles in their respective fields. Trade workers who have completed a Department of Labor-certified apprenticeship and received their journeymen’s license are eligible for a 30-credit-hour block that they can apply toward a bachelor’s degree in construction project management at MSU Denver.

“It’s a great opportunity for skilled trade workers who never thought they’d need to go to college,” said Sandra Haynes, Ph.D., deputy provost at MSU Denver. “They might have gone to work right out of high school, and love what they do, but found out later that in order to move up, they would need a bachelor’s degree. This partnership gives them a springboard to the next step in their careers.”

The program will make it convenient for craft workers to take that step. The additional classes needed to earn a degree will be offered in flexible formats, even possibly on site at one of RK’s two metro Denver facilities. Students will move through coursework together in a supportive learning environment, and may even be given time off during the workday to take classes.

Another major advantage of the program is that students won’t need to stop working full time to take classes, which means they can pay as they go without needing to give up their livelihood or incur debt.

Jon Kinning, the chief operating officer and executive vice president of RK, helped develop the program. He sees it as meeting a need for both his employees and the company.

“In an industry with significant workforce shortages, this program will help us grow our own middle-skilled workers into management roles,” he said. “It could also help show young people who are interested in the trades that this is a viable career path that provides both hands-on skills and upward mobility.”

The curriculum for the CPM degree has been approved and classes are already available, though leaders of both institutions expect the program to ramp up in the fall 2017 semester. The hope is to put together an inaugural class of 15 to 20 students from RK. If successful, the program could be replicated with other companies. It is currently open to any individual skilled trade worker who meets application requirements.

For Robert Park, Ph.D., the director of MSU Denver’s Advanced Manufacturing Sciences Institute, the program sends a clear message to the community.

“These craft workers spend four years as apprentices. That’s as long as it takes to get a traditional undergraduate degree. We want to make sure they know that MSU Denver recognizes the value of those apprenticeships and the skills that they bring to the table.”

One giant leap for student-kind

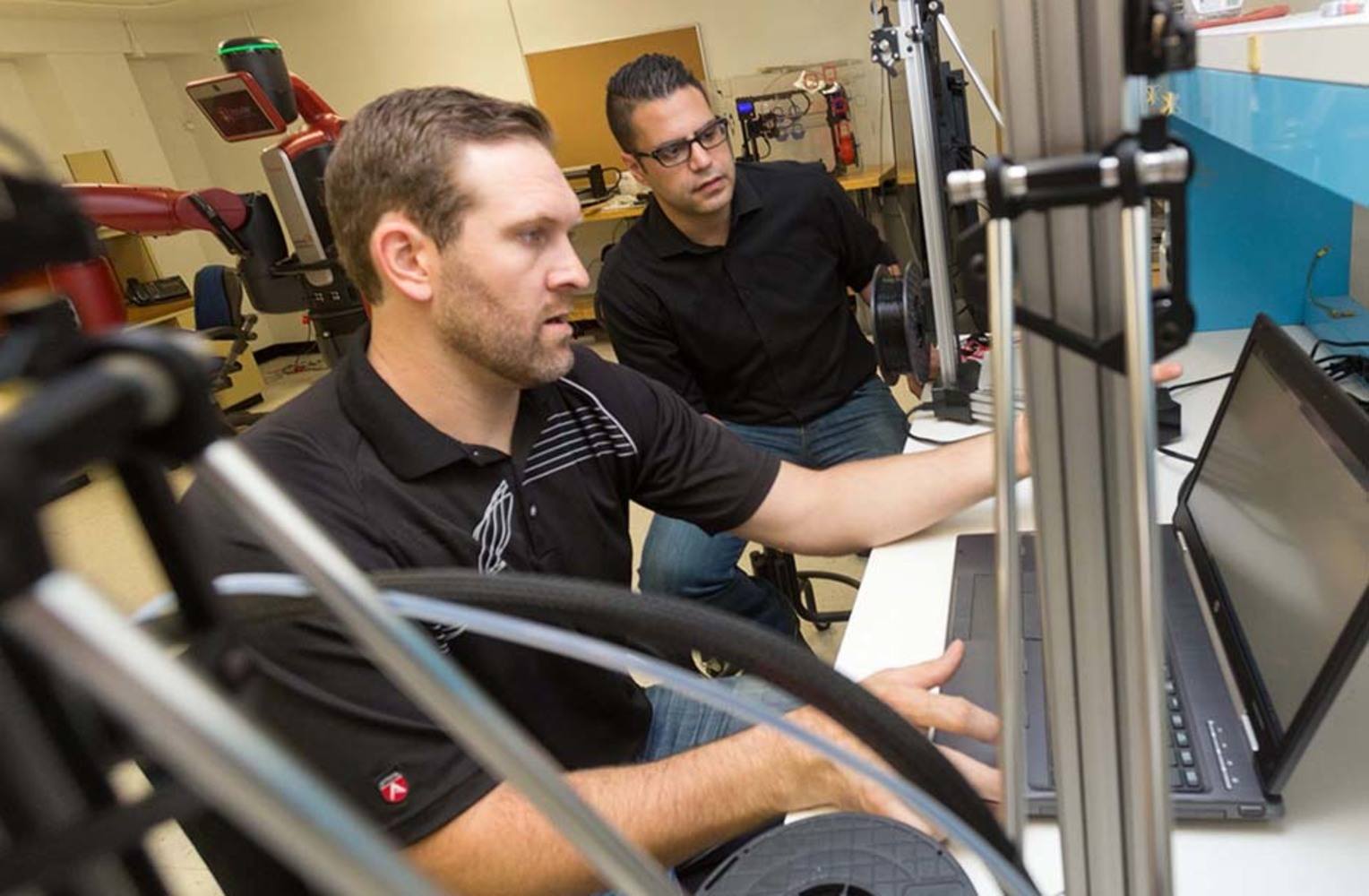

When MSU Denver leaders put together plans for a new Aerospace and Engineering Sciences Building, they designated the top level as a “growth floor.”

The idea was to find an aerospace or advanced manufacturing company that would set up operations there, providing real-world learning experiences to students in the form of exposure and internships.

That idea is now a reality.

The University signed an agreement with York Space Systems, which will bring the company’s new manufacturing facility and mission operations center to the Auraria Campus in time for the AES Building’s 2017 opening.

The facility will house York’s full engineering and design team, production facility, as well as the center, which will operate spacecraft on-orbit, in real-time. In addition to supporting York’s premier mission, the Harbinger Mission, the factory will enable production capability for up to 150-200 satellites per year.

“York Space Systems believes in the potential for Colorado to become a prominent hub for aerospace innovation and our work with MSU Denver presents a unique opportunity to support the training, education and employment of future industry leaders,” said Dirk Wallinger, CEO and co-founder of York. “The public-private partnership agreement with the University will not only further the growth trajectory for the community, but also propel Colorado into the future of aerospace engineering and technology.”

Through the partnership with York, aerospace and advanced manufacturing students from MSU Denver will have the opportunity to collaborate on projects and access internship opportunities, part-time employment and work-study programs to help launch their careers in the aerospace industry.

“It is truly exciting to imagine our students working alongside York’s engineers on the design and construction of satellites that’ll be launched into space and, on top of that, having them participate in the on-orbit control of the satellites they helped build,” said Park. “And this will all be happening right on campus.”