VIDEO: 3D printing PPE for Colorado’s health care heroes

Here’s how MSU Denver’s ‘maker community’ is combining its expertise, ingenuity and resources to design and manufacture much-needed personal protective equipment.

As COVID-19 continues to spread in Colorado, the state’s health care workers on the front lines of the pandemic are in desperate need of personal protective equipment, including medical-grade masks, gloves and medical gowns.

In a March 28 letter to Vice President Mike Pence, Gov. Jared Polis urged the federal government to send more PPE to Colorado as the state’s number of coronavirus cases and deaths continues to rise.

“We are facing a crisis-level shortage of these essential supplies to protect our health care workers and first responders,” Polis wrote to Pence, who is in charge of the U.S. coronavirus task force.

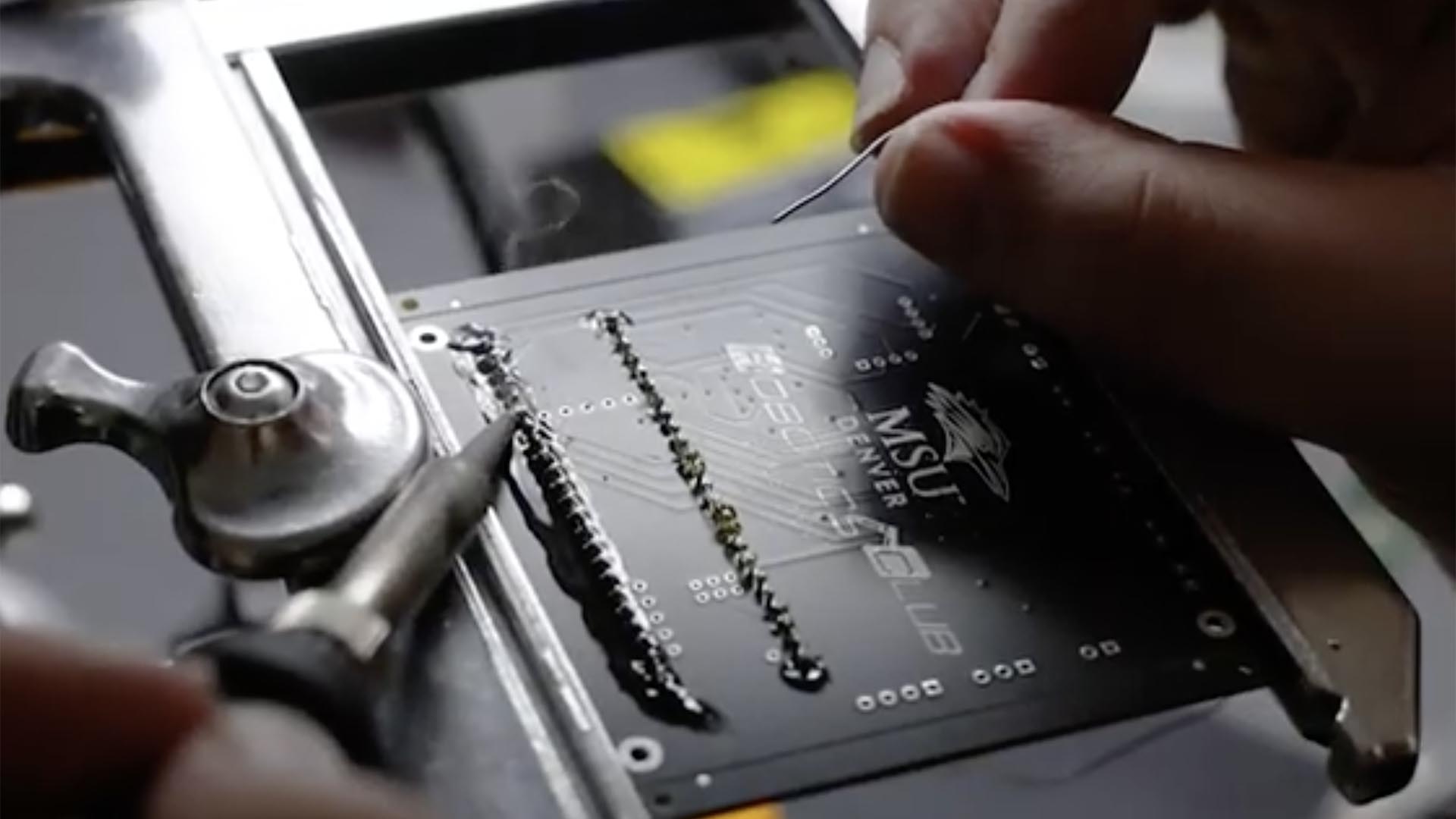

In the face of ongoing supply shortages, communities of makers, including experts from Metropolitan State University of Denver, are stepping up to fabricate 3D-printed PPE for Colorado health care workers.

In the University’s Industrial Design Department, 3D-printing experts are helping produce face shields, said Ted Shin, department professor and chair.

“I’m so happy to be able to use our acumen to help people out. I felt so bad for many weeks, and then one night, I thought, ‘Screw it, I’m going to change this,’” Shin said. “It would be a shame if we could not use this, and I’d feel guilty if I ignored it.”

Printing for a COVID-19 futureAs the MSU Denver community rallies to produce personal protective equipment for local health care workers, its students are designing products for the future. One state model suggests Colorado won’t have its peak number of COVID-19 cases until September, while the Global Preparedness Monitoring Board warned of increasing pandemics in the future in their first annual report last September. The 22 industrial-design students in Professor John Wanberg’s Computer-Aided Modeling class are designing PPE for their final class project, and Wanberg left the assignment intentionally open-ended. “They can design anything that helps mitigate contact that a person would have with the outside environment, like something that could help them to interface with a card reader at the store or open doorknobs. There are a variety of different solutions they can come up with,” Wanberg said. If any of the students’ designs show practical promise, Wanberg says the Industrial Design Department could 3D print them for public use or offer up the designs for download online. Anything intended for medical use would require certification by federal agencies, but nonmedical solutions could be made available immediately. “We might as well give students an opportunity to do something in real time that can help solve some of these problems, using the tools that we’re teaching them at the same time.” Wanberg said.

|

|

Shin, Professor John Wanberg and lab coordinators Will Kellogg and Terry Dreher are alternating shifts in a departmental lab to minimize contact while maximizing output for the dozen 3D printers that have been running since late March.

Even though MSU Denver hasn’t held on-campus classes since March 13, Shin sought out access to the lab and got the green light almost immediately from University leadership after informing them of his plans.

Over in the Advanced Manufacturing Sciences Institute, housed in the Aerospace and Engineering Sciences Building, the call to produce PPE was personal from the start. Karen Cape, the wife of AMSI lab coordinator Jason Butler, is a nurse in the Maternal Fetal Care Unit at Children’s Hospital Colorado. New PPE protocols have maxed out resources at the hospital, and Butler brought the issue to Robert Park, Ph.D., Lockheed Martin endowed director of the AMSI.

Park said his team can manufacture around 90 fully assembled face shields per week with the institute’s state-of-the-art Stratasys Fortus 900 machine, using a design Stratasys provided.

“Jason and I discussed this growing demand issue, and I decided that we should dedicate the full resources of the AMSI to help alleviate the supply shortfall, initially for Karen and her colleagues at Children’s Hospital Colorado in Denver and then beyond, as our manufacturing capabilities and funding allow,” Park said. “This is about the greater good and how the solution has community implications.”

At least 30 MSU Denver employees, students and alumni are actively involved in 3D-printing personal protective equipment on campus, at home or at their businesses. Shin knows of 10 industrial-design alumni who have become professional product designers and are now putting their skills to work to make PPE.

Many are contributing through a statewide maker movement called Make4Covid, an organization that is gathering supplies and policy expertise to provide solutions to the medical-equipment shortage. Make4Covid delivered more than 3,200 pieces of equipment in its first two weeks of existence thanks to more than 1,250 volunteers. Shin’s team produced 120 headbands for face shields its first week before receiving backordered clear plastic for the shields. The team plans to send PPE to the Health Center at Auraria on campus and to alumni and students with connections in hospitals, as well as to Make4Covid for further distribution.

Adrienne Christy, an art and technology support-staff member at MSU Denver, heard about Make4Covid on Facebook and was inquiring into accessing the Art Department’s 3D printers when her chair and dean connected her to Shin’s team. Christy and sculpture studio manager Walter Ware went to campus last week, took 3D printers home and got to work using the face-shield template the industrial designers were already using.

“This project reinforces the mission of the Art Department – providing a challenging and supportive learning environment for those who aspire to professionally practice in visual art, art education, art history and design – while adding a generally unexpected outcome of saving lives,” Christy said. “This can expand our vision for the impact artists have in the community and world.”