CHIPS Act to catalyze Colorado manufacturing workforce development

U.S. Deputy Secretary of Commerce visit to MSU Denver’s Advanced Manufacturing Sciences Institute highlights higher ed’s role in boosting domestic semiconductor production.

Universities will play a crucial role in preparing millions of new tech workers to enter the workforce, as the U.S. seeks to boost domestic semiconductor manufacturing, U.S. Deputy Sec. of Commerce Don Graves said Wednesday during a roundtable at Metropolitan State University of Denver.

Graves joined civic, industry and University experts to discuss the bipartisan CHIPS and Science Act. Enacted August 2022, the federal legislation is poised to inject $52.7 billion into the American semiconductor manufacturing industry; $13 billion is earmarked specifically for research and workforce development, necessitating collaboration between business, government and educators at all levels.

Graves framed the conversation in terms of economic and national security interests, noting the U.S. produces only 12% of the global supply of semiconductors and none of the most advanced microchips.

“That’s going to change,” he said. “The reason I’m excited to be here today is that the partnership between industry and colleges and universities couldn’t be more critical in the coming years. … Schools like MSU Denver and the Advanced Manufacturing Sciences Institute are crucial to helping us meet our goals.”

It’s a daunting task, as the U.S. manufacturing skills gap will potentially leave up to 2.1 million jobs unfilled by 2030. The pandemic supply-chain constraints have served as a moment of reckoning that has required American chip manufacturers to ensure resilience and “not be held hostage by other countries,” Graves added, also noting the need for industry cooperation and export controls to ensure that Russia doesn’t gain access to smart technology that would aid their invasion of Ukraine.

Panelist Maluwa Behringer, executive director of industry partnerships with MSU Denver’s Classroom to Career Hub, spoke to the importance of industry access, equity and wraparound support; the emergence of microcredentials; and outreach to STEM educators in middle schools to inspire students early on.

“Skill development — and diversity of the talent — will be critical,” she said. “We have nearly 5,000 industry partners to help with that. And when it comes to choosing work versus school, it’s not ‘either or.’ I’m hopeful the Earn and Learn model will continue to scale up as these investments come to Colorado.”

Julia Molnar, a graduating senior who is joining Lockheed Martin’s central engineering team in their manufacturing execution systems, credited the University’s industry partnership for launching her career.

“The thing that helped me the most is that industry drives education here, not the other way around,” panelist Molnar said. “The hands-on experience with people who are passionate and come from the field is invaluable.”

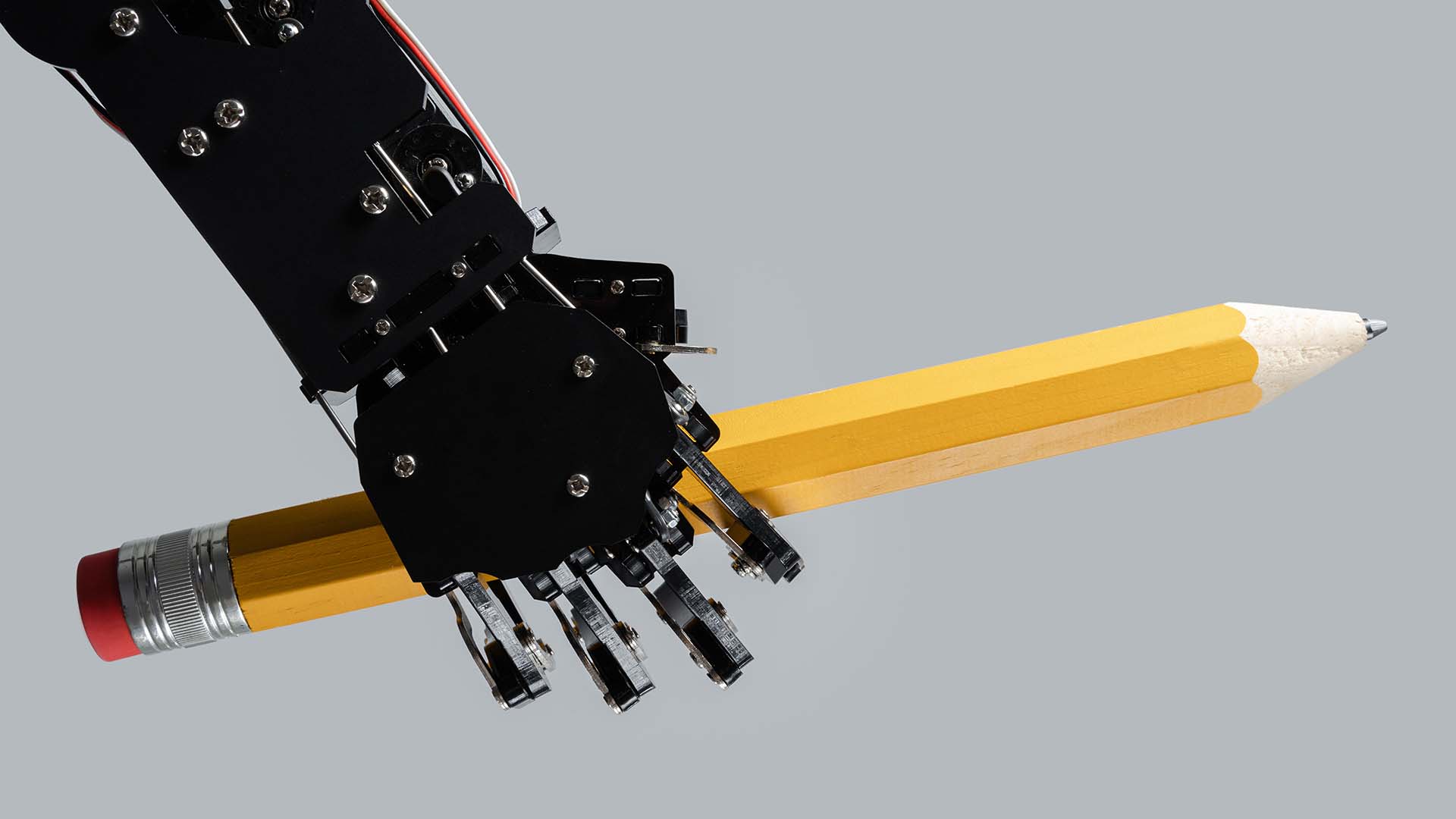

The workforce-driven experience that gets students into the field well before graduation, said Mark Yoss, director of MSU Denver’s Advanced Manufacturing Sciences Institute, is by design a cutting-edge program that prepares students for a new technological era known as the Fourth Industrial Revolution.

“The goal is to blur the line with industry entry,” he said. “We want to get our students working on actual fee-for-service projects with clients, making them more competitive and often leading directly to jobs, while creating an additional revenue stream for the University. It’s a win-win-win.”

Yoss, who will be named the Colorado Manufacturing Advocate of the Year, noted the Institute’s Industry 4.0 Center of Excellence. Kickstarted by a grant from the Colorado Office of Economic Development and International Trade, it’s already leveraging new technology, including augmented reality and digital twins; virtual reality, robotics and artificial intelligence are also planned for future integration. Additionally, four incubator individualized degree programs are aligned with the Manufacturing USA institutes, which are managed by the Departments of Defense, Energy and Commerce.

Given Colorado’s unique position as a tech and aerospace hub and bipartisan legislative efforts to set up a designated manufacturing zone and tax incentives, it’s no wonder Graves chose the Auraria Campus as a backdrop for the work to come.

“Things are happening at MSU Denver that influence the manufacturing ecosystem — it’s a good idea to keep a pulse on what we’re doing,” Yoss said.